Surface Treatment

Surface Treatment

Surface treatment of steel strip

Steel surfaces are treated to be protected against corrosion and to produce decorative surfaces. This is achieved by applying metallic or organic coatings. Surface-treated steel products in the form of strip, sheet and profiles are principally used in the automotive, building, household appliance and packaging industries.

Continuous Hot-dip Coating

Hot-dip coating lines are used to apply metallic coatings to cold-rolled thin sheet and more rarely to hot-rolled strip. The following coatings are produced:

- zinc (Z/GI),

- zinc-iron (ZF/GA),

- zinc-magnesium-aluminium (ZM)

- zinc-aluminium (ZA), Galfan (GF)

- aluminium zinc (AZ), Galvalume (AZ)

- aluminium-silicon (AS).

Strip coating plants are generally operated continuously: individual strips are welded together at the entry area to produce an endless strip which, after coating, is spilt up again and wound into coils at the exit section. The strip arrives in the plant “full-hard”, i.e. directly after cold rolling. It undergoes recrystallising annealing in a continuous furnace under inert gas and is passed through a molten coating bath (bath contents of between 200 and 350 tonnes are usual) containing the liquid coating alloy (at about 450°C for galvanising). The desired coat thickness, usually between 5 and 50 µm, is adjusted by means of gas-knives, wiping off excess molten metal with air or nitrogen. After cooling, the coated strip feeds into the skin pass mill and the tension leveller and can be chemically passivated or phosphated. In the coating line itself, after online surface inspection and online oiling, the coated strip can be prepared for packaging and dispatch to the customers.

Hot-dip galvanised strip is produced in thicknesses of 0.35 to 3.00 millimetres and widths of up to 2,060 millimetres. The maximum speed of a hot-dip galvanising line is about 150 to 220 metres per minute. Depending on the design, the annual capacity of such a plant is about 350,000 to 500,000 tonnes.

Surface treatment technology is subject to constant further development. New plants:

- have vertical furnaces with precise annealing cycles for the production of coated thin sheet, also of high-strength and ultra-high-strength steel grades.

- are equipped with alternative or standby coating pots so that they can produce different coating variants.

- exploit electromagnetic stabilisation of the strip after it leaves the molten coating bath: the thickness of the zinc layer can be adjusted to the optimum because the distance between the gas-knives and the passing strip with the still-liquid coating is kept constant across the whole band width.

- integrate the gas wiping device in a control circuit. State-of-the-art controlling and automatisation technology is combined with the use of neuronal systems for this control circuit to adjust the coating thickness.

- increasingly use cross-process automatic surface inspection.

Continuous Electroplating

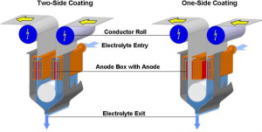

Diagram showing the principle of a Gravitel cell for single-sided and double-sided electrolytic galvanisation of steel (Source: Andritz)

Diagram showing the principle of a Gravitel cell for single-sided and double-sided electrolytic galvanisation of steel (Source: Andritz)A metallic microcrystalline layer of zinc is generated on the surface of the strip during electrolytic galvanising by means of electrochemical deposition. The thickness of the layers achieved using this method usually lie between 2.5 and 10 micrometres and are thus considerably lower than with hot-dip galvanising. Annealed and skin-pass rolled thin sheet is used – with a microstructure that is not subject to any further influence because electrolytic galvanising takes place at room temperature.

After the creation of the endless strip at the entry area, the strip is pre-treated using alkaline cleaning and pickling. Coating takes place in several plating cells, preferably from acid sulphate electrolytes. While early plants were still equipped with soluble anodes, today’s plants have insoluble (horizontal or vertical) anodes. Directly on the electroplating line after the metallic coating has been deposited, the strip is mostly provided with a phosphate layer to enhance the formability of coated sheet during further processing.

Electro-galvanised strip is produced in thicknesses of 0.4 to a maximum of 3.0 millimetres and in widths of up to 1,950 millimetres. Depending on the type of strip, speeds of up to 180 metres per minute can be achieved. The maximum capacity of an electrolytic galvanising plant is about 200,000 to 360,000 tonnes per year, depending on the design and steel grades involved.

Electrolytic tinning

Tinning protects ultra-thin sheet from corrosion and gives it its typical sheen. After cleaning pickling and rising, the strip reaches the electrolytes where tin deposits in the desired layer thickness by varying the current. The surface obtains its typical shiny appearance because it is then briefly heated above the tin melting point of 232°C and then quenched again in a water bath.

The tinplate thus produced is either made directly into a coil, or cut or split for further processing. The tinplate is widely used as packaging material in the food and luxury goods industry.

Tinplate is produced in thicknesses of up to 0.49 millimetres. Electrolytic tinning plants achieve strip speeds of up to 600 to 650 metres per minute and have an annual capacity of up to 390,000 tonnes.

Organic Coating of strip

Coil-coated thin strip is a composite material consisting of uncoated or hot-dip or electrolytically galvanised thin strip and an organic coating, for example in the form of enamel or foil. The special features are corrosion-resistance, formability and a decorative appearance.

The input material (thin sheet in coils) is cleaned and chemically pre-treated. Organic coating materials are applied using a so-called coater, and then dried or cured in a flotation furnace. Coating with plastic foil, using lamination, is another possibility.

Organically coated strip is produced in thicknesses of 0.40 to approx. 2.0 millimetres and widths of up to 1,850 millimetres. Depending on the coating material, layer thicknesses of between 3 and 200 micrometres can be adjusted.

Lines for organic coating can achieve plant speeds of up to 150 metres per minute and, depending on the product mix, have capacities of up to 220,000 tonnes per year.